MANUFACTURING

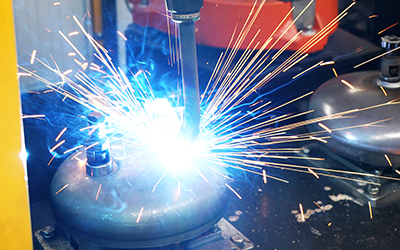

Our 60.000 m2 STATE OF THE ART manufacturing facility located in Konya Turkey is FULLY CERTIFIED and equipped with all the very latest in design, test and manufacturing equipment and is fully supported by our own in house fully accredited High-Tech R&D centre.

Our ALL UNDER 1 ROOF manufacturing policy allows us to offer our customers PREMIUM QUALITY parts and also enables us to launch new parts and new products at a speed to market that is SECOND TO NONE.

Our ever-expanding INDUSTRY LEADING RANGE of parts covering European, Asian, and North American applications helps us meet and exceed all of our partners very diverse vehicle parc needs of today and the future and also ensures we maintain very high vehicle parc coverage across all segments and all markets across the Globe

Product Development is a key activity at ACV, which is supported by a continuous pipeline of regular monthly introductions offering our customers multiple NEW TO RANGE parts within their respective markets.

Our EVER EXPANDING product portfolio comprises of Ball Joints, Axial Joints, Bushes, Tie Rod Ends, Link Stabilisers, Centre Rods, V Bars, Repair Kits and Track Control Arms. Air Tanks, Air Springs, Fifth wheel Repair Kits & Brake Dust Covers.

All of our products are 100% application engineered only using OE parts, ensuring that we offer only THE HIGHEST QUALITY PARTS WITH AFTERMARKET FLEXIBILITY. Every ACV part goes through extensive testing such as dimensional and material checks as well as fatigue and crack detection tests and are also tested to ensure they perform under the most extreme road and weather conditions.

We all know that the aesthetics of a product are as important as the performance and that’s why most of our parts are Cataphoresis plated offering a 10 YEAR GUARANTEE against corrosion.

All of our products are supplied with all the necessary accessories where required ensuring a FIRST TIME FIT.